In today’s fast-moving manufacturing landscape in the UAE, staying competitive means more than just filling orders and dispatching goods. You need complete visibility and control over resources, processes and costs.

Why Manufacturing Resource Planning Matters

In a manufacturing business, resources such as materials, machines, labor and time are precious. A robust MRP system helps you:

Optimize inventory and avoid excess stock or shortages

schedule production accurately and meet delivery commitments

allocate machinery and labor efficiently, reducing idle time

gain real-time insights into progress, costs and bottlenecks

Extensions of MRP increasingly integrate with full ERP suites, enabling you to link production planning with finance, supply-chain, maintenance and business strategy.

For UAE-based manufacturers, the trend is clear: cloud- and mobile-ready ERP/MRP solutions are driving growth and process transparency.

Challenges for UAE Manufacturers — and How We Solve Them

Manufacturers operating in the UAE face unique pressures: tight cost margins, global supply-chain fluctuations, regulatory compliance, multiple site operations across the Gulf region and the need for real-time decision support.

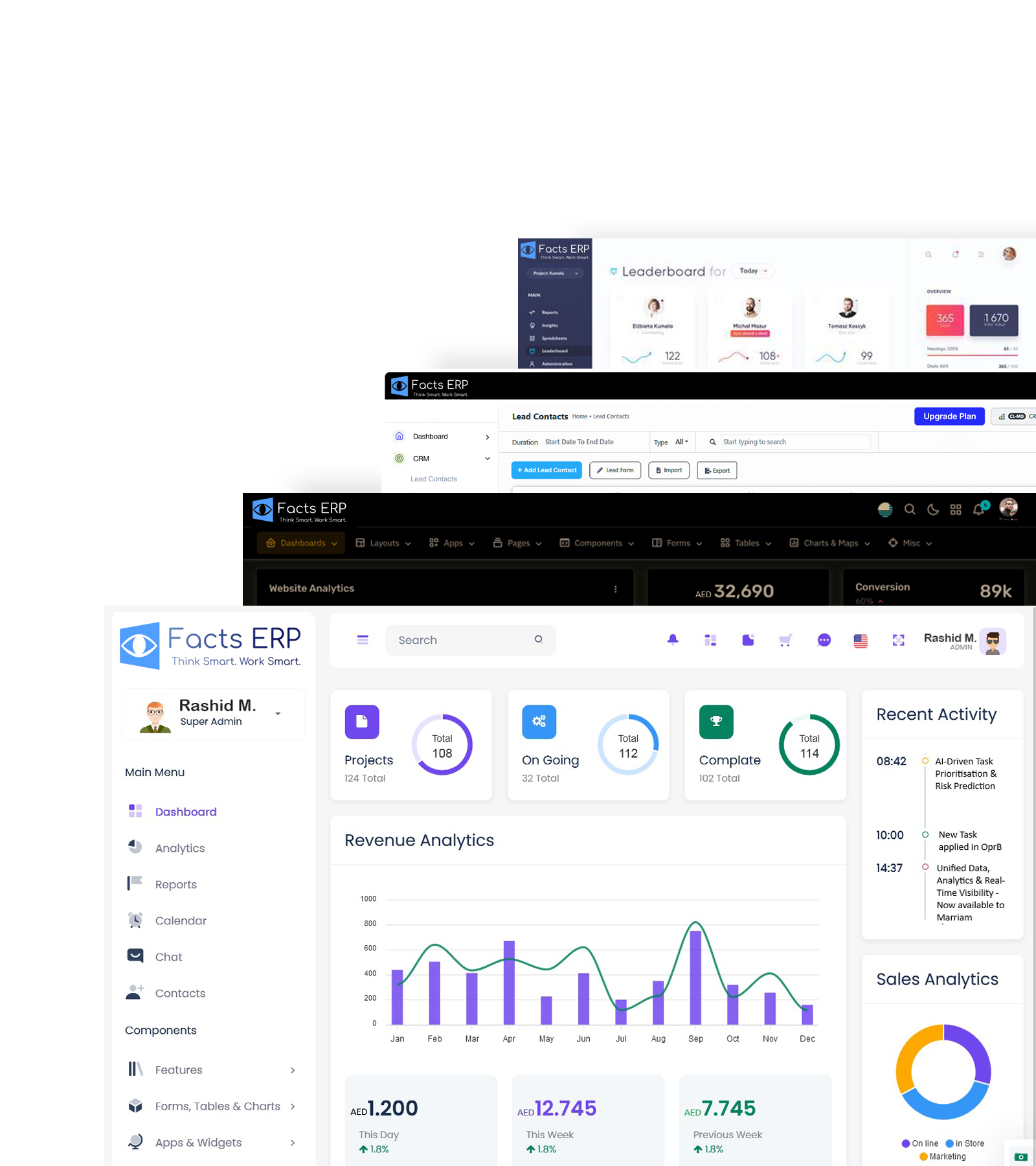

Facts ERP’s Manufacturing Resource Planning solution addresses these needs by offering:

- multi-plant & multi-location support with unified data flow

cloud-based deployment so you can scale without heavy on-premise infrastructure

built-in modules for inventory, procurement, production scheduling, BOM (bill of materials) and quality control

real-time dashboards and analytics so your leadership team can act quickly

These capabilities help you reduce waste, improve delivery reliability, and accelerate growth.

Connect and ask about!

Manufacturing resource planning, MRP system, manufacturing ERP, resource planning software, manufacturing software UAE, ERP for manufacturing, cloud-based manufacturing resource planning for UAE manufacturers, best manufacturing ERP system in Dubai, manufacturing resource planning solution for UAE factories, implement MRP and ERP software in UAE manufacturing industry, manufacturing resource planning software for multi-plant operations UAE, manufacturing ERP with real-time analytics for UAE manufacturing, digital transformation manufacturing resource planning Dubai UAE

Food & Beverage Manufacturing

How ERP Helps

Manage recipe and batch production with accurate material measurement.

Track expiry dates, lot numbers, and compliance with food safety standards.

Automate purchase and inventory control for raw materials like grains, dairy, or spices.

Monitor production yields and reduce wastage through real-time analytics.

Automotive & Spare Parts Manufacturing

How ERP Helps

Synchronize component supply with assembly line schedules.

Manage BOMs (Bill of Materials) for complex multi-component vehicles.

Enable traceability for each part and ensure compliance with quality certifications.

Integrate with supplier and logistics networks for just-in-time (JIT) production.

Textile & Apparel Manufacturing

How ERP Helps

Plan fabric procurement, dyeing, cutting, and stitching sequences efficiently.

Track work orders across multiple production units or subcontractors.

Manage seasonal demand forecasting and raw material stock levels.

Ensure quality checks and color-lot tracking for consistency.

Pharmaceutical Manufacturing

How ERP Helps

Manage formulations, batch records, and production processes under GMP compliance.

Track expiry, lot, and serial numbers for regulatory traceability.

Automate documentation for audits and ISO/FDA compliance.

Integrate with quality assurance and laboratory testing modules.

Furniture & Woodworking Industry

How ERP Helps

Convert custom design orders into accurate production plans.

Calculate material requirements (timber, laminates, hardware) automatically.

Track every production stage — cutting, polishing, assembly, packaging.

Link sales orders with production timelines for on-time delivery.

Metal & Fabrication Industry

How ERP Helps

Plan material cutting and machining based on customer drawings.

Track job costing, welding operations, and CNC machine utilization.

Automate estimation, quotation, and delivery tracking.

Manage subcontractor jobs and raw-material scrap efficiently.

Key Features of Our MRP Solution

- Production Scheduling & Work-Order Management: Align your production plan to customer demand, machine capacity and labour availability.

- Bill of Materials (BOM) & Routing Control: Define every component, operation and assembly route so you maintain clarity and accuracy.

- Inventory & Material-Requirement Planning (MRP): Automatically generate procurement and production suggestions based on demand, current stock, lead-times and capacity.

- Cloud & Mobile-enabled Access: Manage operations from anywhere, get mobile alerts and ensure your team is connected 24/7.

- Shop-Floor Visibility: Monitor status of each job, track machine utilisation, labour hours and identify bottlenecks in real time.

- Quality & Compliance Control: Ensure production meets standards, track non-conformances and maintain audit trails.

- Costing & Performance Analytics: Visualise actual vs planned costs, track efficiency metrics and optimise production run times.

Why Choose Facts ERP as Your Local Partner

When you choose Facts ERP for your MRP and ERP needs in the UAE, you benefit from:

Deep understanding of UAE manufacturing ecosystem — regulatory, regional data-centres, multi-currency and multi-plant operations.

Local support and service model tailored for Gulf region manufacturers.

Proven track record implementing ERP/MRP in manufacturing-intensive environments.

Flexible deployment – cloud, on-premise or hybrid – aligned with your IT strategy.

Ongoing optimisation and enhancement support so you continuously extract value from your investment.